AMC 3D Printer

ZRapid ceramic 3D printing technology can achieve the goal of rapid producing complex customized ceramic products, reducing production costs, and shortening the manufacturing time. The UV laser was employed to cross-link the polymer in the ceramic paste in this technology, which solved the problem that it's difficult to print the ceramic part with complex shape and structure due to brittleness and high hardness of ceramic material in the traditional ceramic molding process.

- Integration of prototyping, debinding, and sintering

- Multi-strategy scan path planning

- Damaged parts can be deleted immediately

- Intelligent partitioning laser scanning

- Remote App monitoring & Smart push

KEY FEATURES

High speed · High precision · High quality

- Intelligent ceramic paste coating device, high viscosity ceramic paste leveling

- Optimize the process, integrated manufacturing routes of ceramic 3D printing

- Programmable user software, convenient to develop new printing materials

- Automatic size shrink compensation in the control software, ensuring the printing accuracy

- Good surface quality, high precision, high repeatability

- Series of high solid content, low viscosity, high fineness ceramic paste, customized materials are also available

-

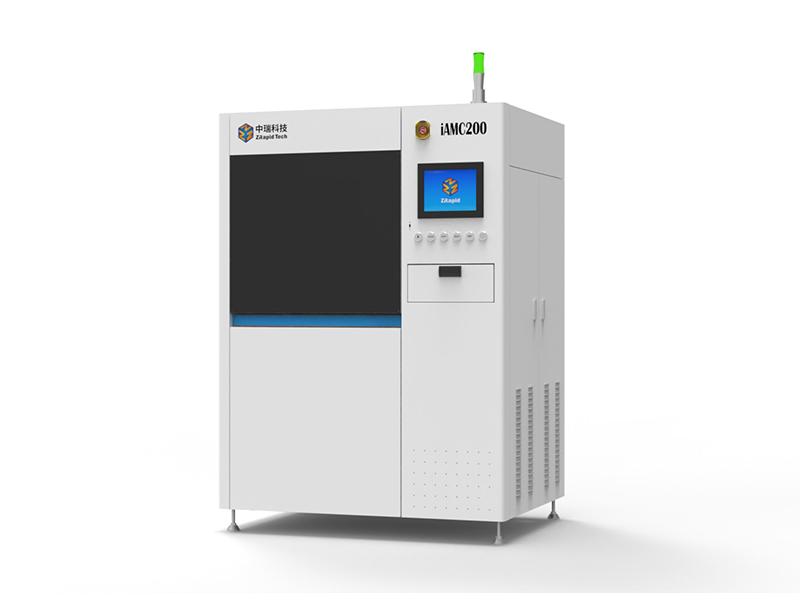

iAMC200 Specifications

LASER SYSTEM

TypeDiode-pumped solid-state laser Nd:YVO₄

Wavelength354.7nm

Laser Power3000mW(Build : 300~1500mW)

RECOATING SYSTEM

RecoatingIntelligent Linkage Double Cylinder Coating System

Normal Build0.05mm

Quick Build0.05~0.1mm

Precision Build0.02~0.05mm

OPTICAL & SCANNING

Beam (diameter@1/e2)0.06~0.12mm

Scanning GalvanometerHigh Speed Scanning Galvanometer

Parts Scanning Speed1.0~4.0m/s (recommended)

Blank Jumping Speed10.0m/s (recommended)

Reference Building Speed2~5cm³/h

ELEVATOR

Position repeatability±0.01mm

Elevator MotorHigh Accuracy Servo Motor

Benchmark Platformmarble benchmark platform

RESIN VAT

VolumeApprox. 8L

XY Platform200mm(X) × 200mm(Y) × 200mm(Z)Not counting screw holes, rounded, etc.

Ceramic PasteSOFTWARE

NetworkEthernet, TCP/IP, IEEE802.3

Control SoftwareiSLA(ZERO 5.0)

Date Preparation Software3dLayer

Data InterfaceCLI file, SLC file, STL file

INSTALLATION CONDITION

Power220V(±10%) AC 50/60Hz, single-phase, 5/10A

Ambient Temperature20-26ºC

Relative HumidityLess than 40%, non-condensing

Size1.40m(W)×1.05m(D)×1.95m(H)

WeightApprox. 700kg

WARRANTY

Laser5000 hours or 12 months (whichever comes first)

Main Machine12 months from installation date

※ The latest data shall be subject to the contract