Jewelry

Love can make people do crazy things – or beautifully creative things. We’ve seen several cases of 3D printed jewelry businesses born from someone’s desire to create something unique and personal for a loved one. For example, extremely talented designer Desmond Chan may never have begun creating 3D printed jewelry if not for his wife, for whom he decided to use his 3D design skills to create a beautiful 3D printed starfish pendant for Christmas. That present in a pinch led to Vulcan Jewelry, a successful 3D printed jewelry business as well as international renown.

Bartłomiej "Bob" Płociennik may not be as well-known or prolific as Chan, but that may soon change. The 22-year-old Polish designer, who just opened his first online shop, started designing at an early age, but his work really began to pick up when he met his girlfriend two years ago.

"I started my sculpting hobby when I was around 13, when I was sculpting miniatures for board games we created with my cousin for ourselves," Płociennik told 3DPrint.com. "When I was at high school I realized that the industry now pretty much requires you to be digital sculptor, to be able to make quick fixes and send your work where it needs to be in a matter of minutes. And so I learned to sculpt in app called Zbrush, and on my first year of college I got full time job as a miniature sculptor. At the same time i dropped my college and started my studio called Nemesis Art Studio."

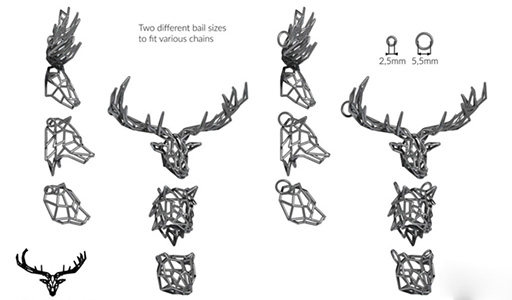

When he began dating his girlfriend, her birthday was approaching, and Płociennik wanted to get her something very special, so he began designing what would become the Bear Bracelet, a delicate piece of 3D printed jewelry featuring the head of a bear. He spent about 30 hours on the piece, working on it in the evenings after his full-time job as well as on the weekends. She loved it, so he followed it up at Christmas with the Deer Pendant, and then the Wolf Pendant.

Płociennik’s girlfriend and friends began urging him to make his jewelry available to the wider public, so he began tweaking his models. Two years later, his first three designs, which he has named the Untamed Line, are available in his Shapeways shop. He told people that he plans to continue with the line whether it proves to be profitable or not, as he loves the work. The next two pieces he plans to add to the collection will be a cat and an owl.

Płociennik shared some details about his design process with us:"So first step is to gather resources, as many good reference photos as possible, it was especially important when making deer’s antlers, but was also inevitable when sculpting far simpler wolf or bear. Next step for me is creating pretty realistic bust of the creature. It takes a lot of time and is important step if you want to end up with recognizable silhouette. Then it comes time for simplifying still as a solid. The goal is to portray what you see with as few planes as possible. After this step is done, all there is left to do is follow edges with long cylinders, merging those cylinders into one mesh, smoothing connections and adding bails. Then the file goes to printing factory and soon is ready for customers."

He may be only 22, but Płociennik’s artistic, attractive jewelry (modeled on Shapeways by his girlfriend, Katarzyna Kowalczyk) shows a level of skill that reflects how much time, effort and natural talent he has put into his craft.

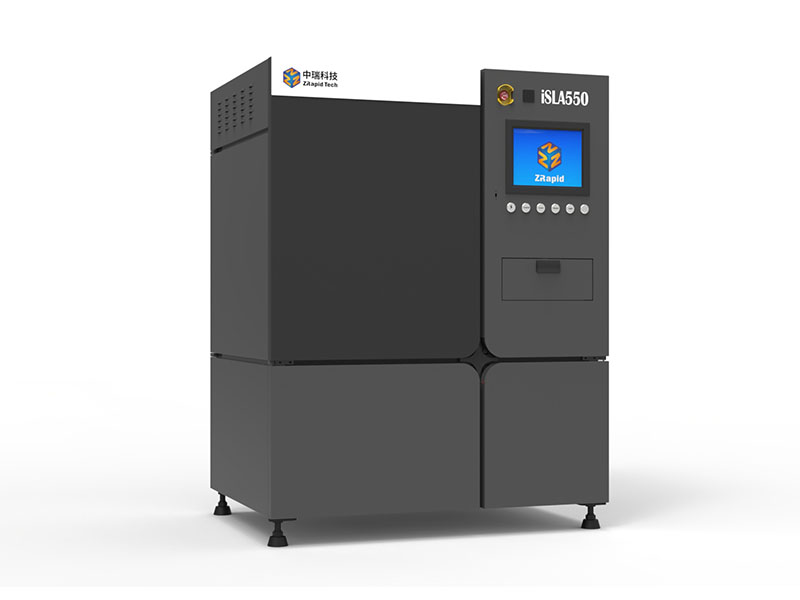

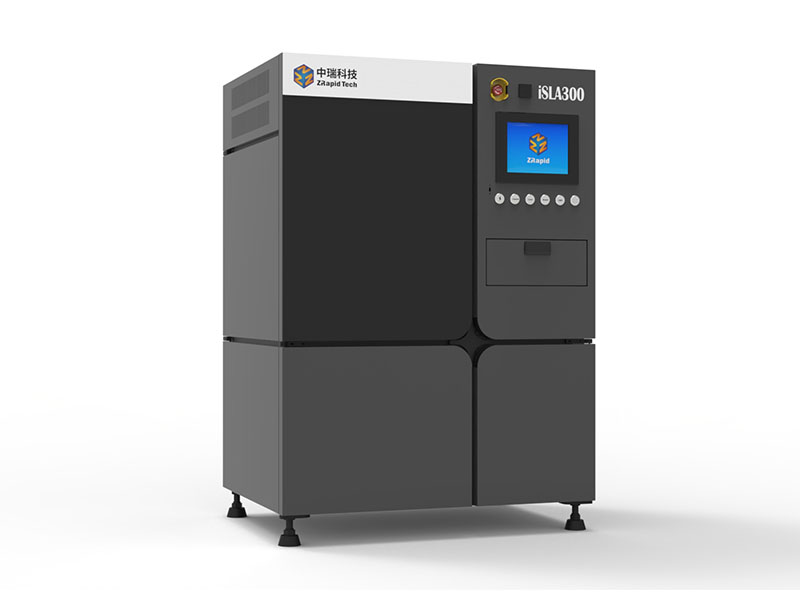

The traditional jewelry manufacturing process is combined by the silver model making / pressure film / open mold / wax / repair mold and other sets of procedures, it takes lots of complex procedures, equipment / site / material / manpower and time cost. Compared with the traditional handmade craft, designers need to focus on the process in the design of jewelry to get the final product. 3D printing, to a large extent, can be a additional tools of the transitional work, it removed a lot of links, and greatly shortened the work time. In addition, no matter how strange the shape / how unique the idea and design, 3D print can make it done, which is the traditional process can not do.

To get the accurate jewelry of the designer, people need very high skill carved master.While 3D Printers can easily make a variety of wax mold, and perfectly fit the designer's design model, greatly reducing the model making time / errors and unnecessary losses, while also ensuring the high quality and accuracy of the model, thereby reduced the production costs, and increased production efficiency greatly.

3D Printers directly print the wax mold, and then get the silver model followed by loss of wax casting process, and then conduct the pressure film and a series of other processes. Now, 3D Printers has been able to completely replace the manual version of the process, for mass production, suitable for factory mass / standardized production.