Medical

3D medical printing is based on a three-dimensional model, through the method of discrete layered software and CNC molding, positioning and assembly of biological materials or living cells, manufacture the medical assistance devices, implanted stents, 3D printing organs and other medical Product, 3D medical printing is the most advanced research in 3D printing technology field.

Three reasons for the huge development of 3D medical printing

- The huge expenditure in the global medical field provides a potential development space for 3D printing technology;

- 3D printing technology is known for its efficiency and accuracy, the personalized manufacturing perfectly meets the individual different requirements, produce a huge boost effect in the artificial prosthesis and artificial organs;

- Compared with other fields, the application of 3D printing in the medical industry is more economical.

Application status of 3D printing in medical field

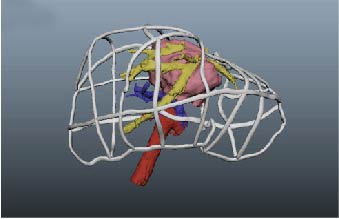

Before the operation, doctors can build 3D model through 3D printing, have a better plan and more confident for the operation. Meanwhile, It is easier for doctors to explain the conditions to patients, build up a good relationship between doctors and patients.

3D print surgical guide, is an important auxiliary tool for surgery. It is not completely rely on doctors experience. It is more reliable and safe. At present, 3D printing operation guide plate are applied in multiple disciplines including arthritis plate, spinal plates, dental implant guide etc.

Implant parts

3D printing can print out high precision complex parts. The doctor can use 3D printing to print out the parts completely fit for patients. For example, patients with a bone necrosis, need a replacement, the doctor can scan the specific parts of the patients before the replacement, and then print out the substitute exactly same shape as the bone to implant.

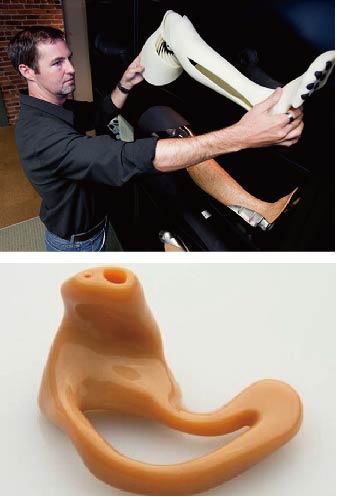

Rehabilitation Instruments

For the customized rehabilitation equipment, before 3D printing, needs only the patients scan data than can print out the high complexity and high degree of fit of rehabilitation instruments.

Dental application

In recent years, the Department of Stomatology have introduced 3D print, with its high accuracy, low cost advantages to improve the efficiency of Stomatology. In 2015, 3D printing up to $721 million in Stomatology of the market share, mainly used in the manufacture of dental crowns, bridges, model, and invisaligner. Experts predicted: the market share will be to reach $2.3 billion by 2020.

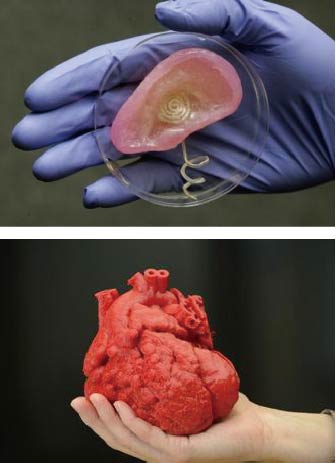

Biological 3D Printing

The ultimate aim is to print human organs and tissues directly to repair or replace the affected area. At present, the United States, Europe, Australia, Russia, China have made some progress, but most of the projects are still in the experimental stage.

Medical Industry Samples

Case 1

In April 9, 2013, a Japanese hospital doctors cut a three-dimensional copy of a 3D printing liver. This model helps doctors figure out how to cut the liver, and they successfully transplanted the liver.

Case 2

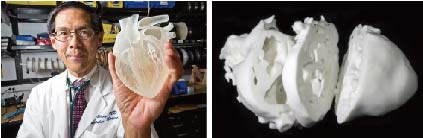

Congenital heart defects are the most common types of birth defects in newborn babies each year, nearly 1% have such problems. It is very challenging for a doctor to operate a cardiac surgery on a not fully grown,small and delicate organs of an infant. Kosair children's Hospital in Kentucky, Louisville, cardiac surgeon Erle Austin, before the complex operation of a child suffering from heart disease, with the planning and experimental of a 3D printing model, guaranteed success of the operation.

Case 3

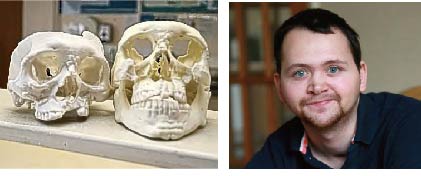

Days ago, the British surgeon successfully repaired a male patient’s face with the help of 3D printing technology. Unfortunately the man fell on the concrete floor from a four storeys roof. Jon Fenton’s skull in a disastrous state after the accident, the whole lower jaw disappeared. The 3D printing mandibular model helps surgeons to make accurate judgement of the patient’s condition. "According to this model, we can make the operation plan, and carry out the preparatory work." Dr. DilipSrinivasan said, he is responsible for supervising the whole process. "This operation is very complicated, but we had the operation planned. We only need to carry out the plan and that's all."

Case 4

For this kind of auxiliary support fracture, First we need the 3D print scanning data of patient’s wounds, and then print out through the 3D printing technology. It’s much better appearance than the plaster. First the material of 3D printing structure is plastic, and is porous, so very light and ventilated and even water proof; Second ,because it making out of 3D scanning data so it has better fit effect and stronger bracing; Finally, the Osteoid Cast can also be added with ultrasound promoting bone growth device, so that patients can recover faster and better.

Case 5

When Natasha Hope-Simpson first saw the specially designed 3D printing made leg for her, She filled with joy immediately. She said that even better than she thought. The 24 year old woman suffered a serious car accident in November last year, she spent 5 weeks in the hospital and lost her leg forever. She used a functional artificial limb first, but it doesn’t look good. So the undergraduate from the University of NSCAD contacted ThinkingRobo studio in Canada, hoping to design a better looking leg for her.

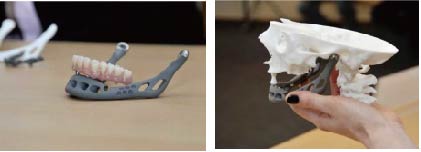

Case 6

In February 10, 2012, the Belgian Hasselt University researchers announced that they have successfully implanted a 3D printing mandibular for a 83 year old woman. This is also the first time fully use customized implants to replace the entire jaw in the world. In order to avoid the occurrence of rejection, researchers coated the artificial mandible with bio ceramic. It is reported that the use of 3D printing technology to produce artificial jaw weighs about 107 grams, 30 grams of weight higher than the living jaw, so it is very convenient to use for patients.