Aerospace

The necessity of introducing 3D printing into aerospace

- Aeronautical Product Innovation / Update frequency

- Shortening the development cycle

- Increasing requirements for complex and sophisticated construction

- Efficient / fast manufacturing, becoming the core competency of aerospace

International investment in 3D printing in Aerospace field

- UKThe R & D project for the "Horizon (AM)" accounts for one-third of the UK's major new investment to promote the development of the aerospace industry. In September 2012, the UK Technology Strategy Committee reported in the "Shaping our National Competency in Additive Manufacturing" that they take 3d printing as the primary application of Aviation Aerospace field.

- USAIn 2006, the US Department of Defense "next generation manufacturing technology" program focused on supporting 3D printing technology research and application;

In 2009, the US developed a 3D print development road map, taking 3d printing as the aerospace first demand industrial application goals;

In 2012, the US Department of Defense led the US manufacturing (AMERICA MAKES), dedicated to 3D printing technology research / technology transfer / standard setting / personnel training and mainstream manufacturing promotion and application. - GermanyEstablished a direct manufacturing research center, mainly research and promote the additive manufacturing technology in the Aerospace field in the application of lightweight structure.

- AustraliaIn 2012, the government announced a support for the Aerospace field, a revolutionary project, "miniature engine weighting manufacturing technology," which uses the additive manufacturing technology(3d printing) to manufacture micro-engine parts for Aerospace field.

- JapanThrough the preferential policies and a lot of money to encourage the close combination of production and research, effectively promoted the application of the 3D Printing technology in the field of aerospace and other industries. Mitsubishi Heavy Industries has been using metal 3D printing in the rocket development process.

China 3D printing in Aerospace field

In October 2012, Lu Yongxiang, vice chairman of the Standing Committee of the National People's Congress, made a speech on the 3D printing application of aerospace field, which place the 3D Printing as the top application for aerospace.

In 2015, the Ministry of Industry promulgated the National Additive Manufacturing Industry Development Promotion Program (2015-2016), proposed the development of 3D printing objectives: to 2016, China will initially establish a more complete production industry, the overall technical level shall maintain international synchronization, to achieve the international advanced level in the field of aerospace and other direct manufacturing, to occupy a larger market share in the international market.

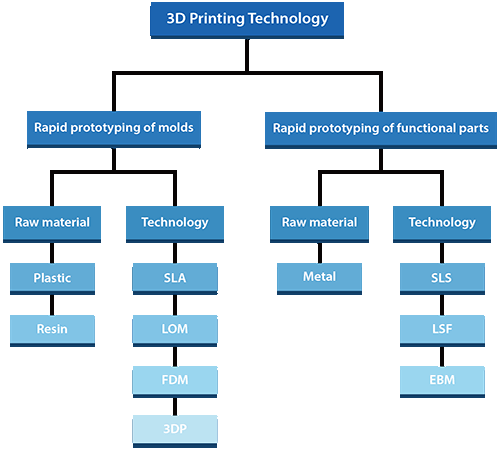

3D printing materials and technology in aerospace

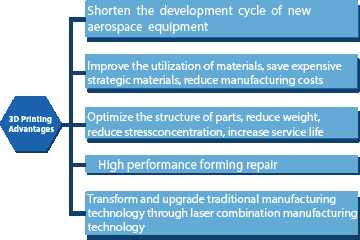

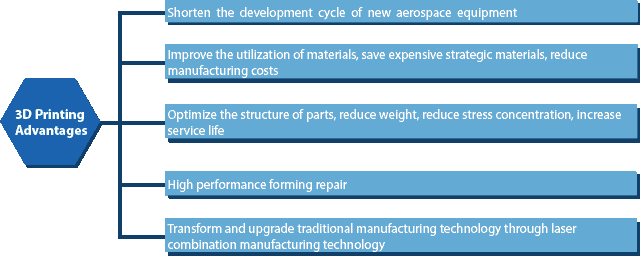

3D printing highlights the advantages in aerospace

3D printing research results in aerospace

Case 1

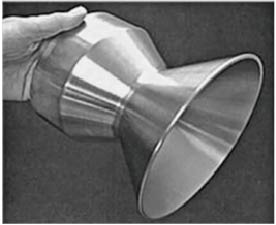

US San-dia National Laboratory uses LAM technology to create SM3 missile three-dimensional guidance and attitude control rhenium alloy nozzle, which reduced manufacturing cost 50% lower and manufacturing cycle.

Case 2

In March 7, 2013, J-2X rocket engine main contractor - the United States Pratt & Whitney Locke company uses selective laser sintering technology (SLS) to create the engine exhaust cover, J-2X rocket engine was tested in a harsh environment and got success.

Case 3

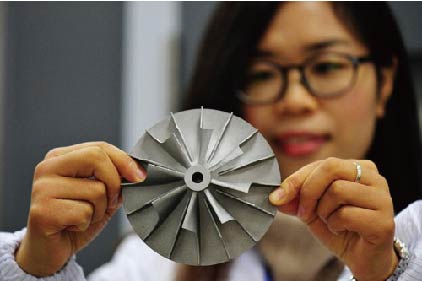

GE's research team has designed a full-featured small jet engine for a radio-controlled aircraft that embody all the benefits of 3D printing, they redesigned the RC engine and printed it directly using 3D printers. The engine speed is up to 33,000 RPM.

Case 4

Pratt & Whitney relies on MTU Aircraft Engine Company to conduct SLM technology to directly manufacture testing parts of Purepower PW1100G aircraft engine.

Case 5

The biggest star of the Zhuhai Air Show - J-31 “Urik” fighter, with a large number of 3D printing components, including titanium spar. J-31 is 17 meters long, wingspan is 11.5 meters, it is the similar size of the US F35 “Lightning” Ⅱ, smaller then F22/J-20. Once served, the J-31 may be combined with the J-20 to make a “high and low” combination, similar like the US Air Force F35 and F22 combination. J-31 may also be served on the Aircraft carrier.

Case 6

3D printed LEAP engine successfully fly into the sky. Engineers use 3 kilowatts electron guns to accelerate the electron beam melting powder titanium aluminide. Electron gun power is 10 times stronger than currently used laser beam, it is used for the processing of Titanium Alloy blades, while titanium aluminum alloy blades can reduce 20% weight of the turbine. In addition, 3D printing is also used in the manufacture of fuel injectors.

3D printing potential in the aerospace

VIVEK SAXENA, Vice President of International Aviation from Technical Consultant ICF : additive manufacturing (3D Printing) currently accounts for 0.0002% of the global manufacturing market. The ratio of Aerospace field is approx. 0.002%, the total aviation parts market is approx. $ 150 billion. However, SAXENA predicts that 3D printing parts will reach $ 2 billion in the aerospace component market over the next decade.